Welcome to the world of logistics! You are reading this article because you are either looking to choose between a 4PL and 3PL provider or you are simply interested in learning more about warehousing and logistics. Either way, our team at Green Retail Consulting is here to help.

What is a 4PL?

In the realm of logistics providers, Fourth-Party Logistics (4PL) has emerged as a prominent solution for businesses seeking comprehensive supply chain management. A 4PL provider acts as an external entity that takes on the responsibility of orchestrating and optimizing the entire supply chain on behalf of a client. Unlike Third-Party Logistics (3PL) providers, who offer specialized logistics functions, a 4PL provider assumes the role of a central coordinator, overseeing multiple 3PL partners and collaborating with various stakeholders. The 4PL serves as the single point of contact, offering an integrated and holistic approach to logistics management.

In other words, 4PL companies manage 3PL companies to optimize their supply chain and create standardized, end-to-end solutions.

What is a 3PL?

Conversely, Third-Party Logistics (3PL) companies are often established players in the logistics industry. A 3PL provider is an external service provider that offers a range of logistics services to businesses. These services may encompass transportation, warehousing, inventory management, order fulfillment, and more. The primary focus of a 3PL is to handle specific logistics functions on behalf of its clients, allowing businesses to outsource certain aspects of their supply chain management and concentrate on core competencies.

You can also think of 3PL companies as handling the day-to-day logistics of your supply chain as 3PLs often own assets like warehouses or transportation.

Characteristics of a 4PL

To gain a deeper understanding of the capabilities of a 4PL provider, let's explore some key characteristics that typically define a 4PL provider:

- End-to-End Supply Chain Management: The hallmark of a 4PL is its capability to manage the entire supply chain from its initiation to the final delivery. This includes overseeing the operations of multiple 3PL providers, seamlessly integrating their services, and optimizing the entire logistics process.

- Centralized Control: Opting for a 4PL enables businesses to centralize their logistics operations, entrusting the 4PL provider with the responsibility of coordinating and executing logistics activities on their behalf. This centralized control fosters streamlined communication, reduced complexities, and a comprehensive view of the entire supply chain. Unlike working with multiple 3PL providers and navigating multiple streams of communication, you only have to speak with your 4PL provider to understand your company’s logistics process.

- Technology Integration: 4PL providers rely on sophisticated technologies to efficiently manage complex supply chains. These technologies may include advanced tracking systems, analytics tools, and supply chain management software. By leveraging cutting-edge technology, 4PLs can provide real-time visibility into logistics operations, empowering businesses to make data-driven decisions and respond swiftly to any supply chain disruptions.

- Data-Driven Decision Making: In the modern era of logistics, data reigns supreme. 4PL providers are adept at collecting, analyzing, and interpreting vast amounts of data from various sources, including 3PL partners, internal systems, and external market trends. This data-driven approach empowers businesses to optimize their supply chain, identify bottlenecks, and continuously improve performance.

- Collaborative Network: 4PL providers foster a collaborative network as they work with multiple 3PL partners and other stakeholders. By promoting seamless communication and coordination among all players, a 4PL ensures that each component of the supply chain functions harmoniously, leading to improved efficiency and reduced lead times.

3PL vs. 4PL

Now, let's delve deeper into the the primary similarities and differences between 3PL and 4PL logistics models:

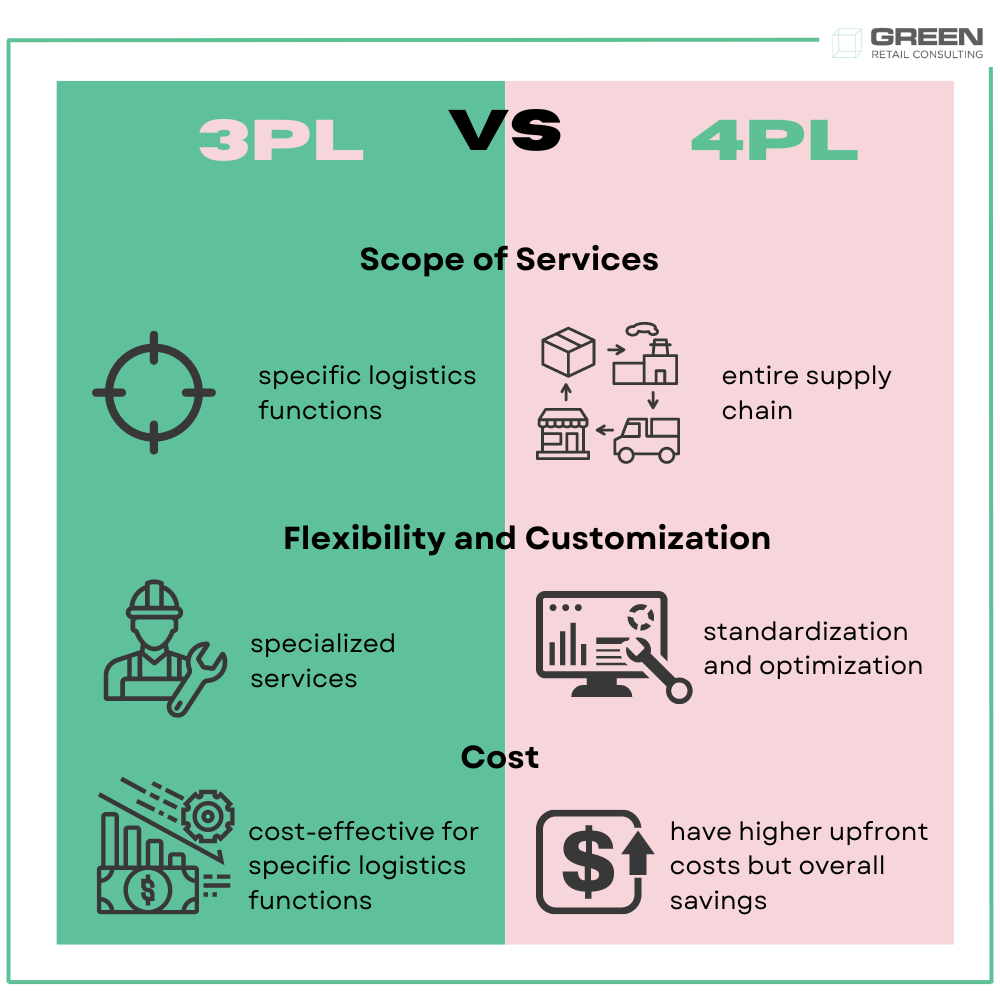

- Scope of Services: The primary difference between 3PL and 4PL lies in the scope of services they offer. As mentioned earlier, 3PL providers specialize in specific logistics functions, such as transportation, warehousing, or distribution. In contrast, 4PL providers take a more comprehensive approach, managing the entire supply chain from procurement to delivery. This broader scope allows 4PLs to create more integrated and streamlined logistics solutions.

- Level of Control: Another key distinction is the level of control that businesses have when working with 3PL and 4PL providers. In a 3PL arrangement, businesses retain some level of control over their logistics operations. They collaborate closely with the 3PL provider, overseeing and managing various aspects of the supply chain. This level of involvement can be advantageous for companies that prefer to have direct control over specific logistics functions or strategic decisions.

On the other hand, a 4PL provider takes full control and responsibility for the supply chain. By acting as the single point of contact, they become the central orchestrators, coordinating all logistics activities and 3PL partners on behalf of the client. This centralized control can be beneficial for businesses seeking to minimize their involvement in day-to-day logistics management and focus on their core competencies.

- Flexibility and Customization: Flexibility is an important consideration for businesses with unique logistics requirements. 3PL providers often excel in providing specialized services that can be tailored to meet specific business needs. They offer a range of options and can adapt their services to accommodate changing demands.

In contrast, 4PL providers may face challenges in offering the same level of customization due to their emphasis on standardization and optimization across the entire supply chain. While they provide a more streamlined and integrated logistics solution, this standardized approach may not always align perfectly with the unique needs of every business.

- Visibility and Transparency: Both 4PL and 3PL can offer improved visibility into logistics operations, but 4PLs typically provide more extensive tracking and reporting capabilities. By overseeing multiple 3PLs and utilizing advanced technologies, 4PL providers can offer real-time data and insights on the entire supply chain, enabling businesses to make more informed decisions.

The greater visibility provided by 4PLs can lead to better coordination, risk management, and performance optimization. However, 3PLs can still provide valuable visibility into their specific logistics functions, especially when they use modern tracking and reporting tools.

- Cost Considerations: Cost is an essential factor for any business decision, and logistics is no exception. 3PL providers may offer more cost-effective solutions for specific logistics functions, making them attractive for businesses with limited budgets or those seeking targeted logistics outsourcing. By choosing different 3PL providers for different functions, businesses can take advantage of competitive pricing and specialized expertise.

On the other hand, 4PLs may have higher upfront costs due to the comprehensive services they offer and their use of advanced technologies. However, in the long run, a well-executed 4PL partnership can lead to overall cost savings through supply chain optimization, better negotiation with multiple service providers, and reduced inefficiencies.

How the 4PL Process Works

Understanding the 4PL process sheds light on how these providers manage and optimize supply chains. The 4PL process can be broken down into several key steps:

Step 1

Assessment and Planning: The first step in the 4PL process involves a thorough assessment of the client's existing supply chain. This includes understanding the business's logistics requirements, identifying pain points, and setting objectives for improvement. The 4PL provider works closely with the client to gain insights into their logistics strategy, operational capabilities, and overall business goals.

The assessment phase is critical as it forms the foundation for the entire logistics solution. The 4PL provider must have a comprehensive understanding of the client's supply chain challenges and opportunities to develop an effective logistics strategy.

Step 2

Design and Integration: After completing the assessment, the 4PL provider designs a comprehensive logistics solution tailored to the client's specific needs. This involves creating a detailed logistics plan that addresses each aspect of the supply chain, from procurement to distribution.

One of the key aspects of the design phase is the integration of various logistics functions and 3PL partners. The 4PL provider works to establish seamless connections between different elements of the supply chain, ensuring smooth communication, efficient data sharing, and coordinated efforts.

Step 3

Vendor Selection: As part of the 4PL process, the provider must carefully evaluate and select appropriate 3PL partners to fulfill different logistics functions. This selection process is crucial, as the effectiveness of the entire supply chain hinges on the capabilities and reliability of the chosen 3PL partners.

The 4PL provider conducts thorough research and due diligence to identify potential 3PL partners with a proven track record, industry expertise, and the ability to meet the client's specific requirements. Negotiations with potential partners include discussions on service offerings, pricing, performance metrics, and contractual terms.

Step 4

Implementation and Execution: With the logistics network in place and the 3PL partners selected, the 4PL provider takes charge of executing and managing the providers and ensuring seamless day-to-day logistics operations. This includes overseeing the movement of goods, coordinating activities among the 3PL partners, and ensuring that shipments are delivered on time and in compliance with agreed-upon service levels.

During the implementation phase, the 4PL provider plays a crucial role in resolving any logistical challenges and ensuring smooth operations. Effective communication and collaboration among all parties is vital to maintaining supply chain efficiency and meeting customer expectations.

Step 5

Monitoring and Optimization: The 4PL process doesn't end with implementation—it does not actually end since it is an ongoing and iterative cycle of improvement. The 4PL provider continuously monitors the supply chain's performance, analyzing data and key performance indicators (KPIs) to identify areas for improvement.

By leveraging data analytics and business intelligence tools, the 4PL provider gains valuable insights into supply chain performance. These insights are used to make data-driven decisions, identify bottlenecks, and implement optimization strategies to enhance efficiency, reduce costs, and improve overall supply chain performance.

Which Type of Logistics Model is Best for You?

Now, let's answer the burning question: which logistics model is the best fit for your business? The answer depends on several factors unique to each organization. Here are some considerations to help you make an informed choice:

- Complexity of the Supply Chain: If your supply chain is highly complex, involving multiple locations, transportation modes, and inventory management challenges, a 4PL's holistic approach may be more suitable. Complex supply chains often require tight coordination among different stakeholders, and a 4PL can act as the central orchestrator, ensuring seamless operations and optimal performance.

- Resource and Expertise Availability: Consider the level of expertise and resources available within your organization to manage logistics effectively. While a 3PL can provide specialized services for specific functions, your in-house capabilities may still be responsible for overseeing these functions if the 3PL does not offer these services. If you lack the necessary expertise or resources to manage logistics efficiently, a 4PL can provide the necessary support and expertise.

- Cost and Budget Constraints: Assess your budget and cost expectations for logistics management. 3PL providers can offer specialized services at a lower cost, making them attractive for businesses with limited budgets. If you have budget constraints but require specific logistics functions to be outsourced, a 3PL might be a more suitable option.

- Long-Term Logistics Strategy: If you are looking for a long-term logistics strategy with ongoing optimization and improved supply chain visibility, a 4PL or 3PL partnership can provide valuable insights and support. A 4PL's focus on end-to-end supply chain management and data-driven decision-making can help your business stay competitive and agile in a rapidly changing marketplace. However, the right 3PL provider can also ensure a competitive edge to your supply chain.

- Industry and Market Considerations: The choice between a 4PL and a 3PL can also be influenced by the industry in which your business operates and the unique characteristics of your market. For industries with stringent regulatory requirements, complex supply chains, or rapidly changing customer demands, a 4PL's comprehensive approach may be better suited to address these challenges.

Reach out to our team at Green Retail Consulting if you have any questions about whether to choose a 3PL or 4PL provider based on your business’s long-term goals.

Top 5 FAQs when Choosing a 4PL or a 3PL Provider

Before we wrap up, let's address some frequently asked questions about 4PL and 3PL:

- What are the key advantages of 4PL over 3PL?

The primary advantages of 4PL include holistic supply chain management, centralized control, advanced technology integration, and data-driven decision-making. A 4PL can provide businesses with a comprehensive logistics solution that optimizes the entire supply chain, improves efficiency, and reduces lead times.

- Is 4PL more expensive than 3PL?

While 4PL may involve higher upfront costs, it can lead to overall cost savings in the long run. The centralized control and optimization capabilities of a 4PL can result in more efficient supply chain operations and better negotiation with multiple service providers, leading to cost reductions. However, the right 3PL provider can be less expensive upfront while creating long-term cost savings through supply chain optimization.

- Are there any industries where 4PL is more commonly used?

4PL can be beneficial for industries with complex supply chains such as retail, healthcare, automotive, electronics, and e-commerce. These industries often face unique logistical challenges such as managing multiple distribution centers, coordinating global shipments, and responding to dynamic customer demands. A 4PL's comprehensive approach can help these industries achieve greater supply chain efficiency and agility.

- How does a 4PL provider select and manage 3PL partners?

The success of a 4PL partnership relies heavily on the selection and management of 3PL partners. 4PL providers conduct thorough research and due diligence to identify potential 3PL partners with the required expertise, capabilities, and track record. They assess factors such as service offerings, industry experience, financial stability, and geographical coverage.

Once 3PL partners are selected, the 4PL provider maintains ongoing communication and collaboration with them. Regular performance evaluations and adherence to Service Level Agreements (SLAs) help ensure that 3PL partners meet agreed-upon standards and deliver high-quality services. By fostering a collaborative network, the 4PL provider ensures that all players in the supply chain work together seamlessly.

- Can a business switch from 3PL to 4PL, or vice versa?

Yes, businesses can transition between logistics models based on their changing needs and objectives. The decision to switch from 3PL to 4PL, or vice versa, should be made after thorough analysis and evaluation of the logistics requirements.

Businesses considering a switch to 4PL should assess the complexity of their supply chain, the level of control they desire, the availability of internal resources, and the long-term logistics strategy. Similarly, businesses considering a switch to 3PL should evaluate the specific logistics functions they want to outsource, cost considerations, and the desired level of flexibility.

The transition process should be well-planned and executed to minimize disruptions to the supply chain and ensure a seamless integration of services.

Conclusion

Congratulations on learning more about 4PL and 3PL providers! You are now equipped with the knowledge to navigate the exciting world of logistics and make the best choice for your business. Whether you choose the standardized 4PL or the more specialized 3PL, the key is to find the logistics solution that aligns with your unique needs and goals.

Remember, logistics is like a puzzle, and with the right logistics partner, all the pieces will fit together seamlessly. So go forth and take on logistics challenges with confidence. Happy shipping!

If you would like recommendations on stellar 4PL and 3Pl providers or still have questions on whether to choose a 3PL or 4PL, feel free to set up a free 30 minute consultation with our team at Green Retail Consulting.

Leave a Comment